Cyclic Drying Line For Painting Of Bicycle Frame (Patent Design)

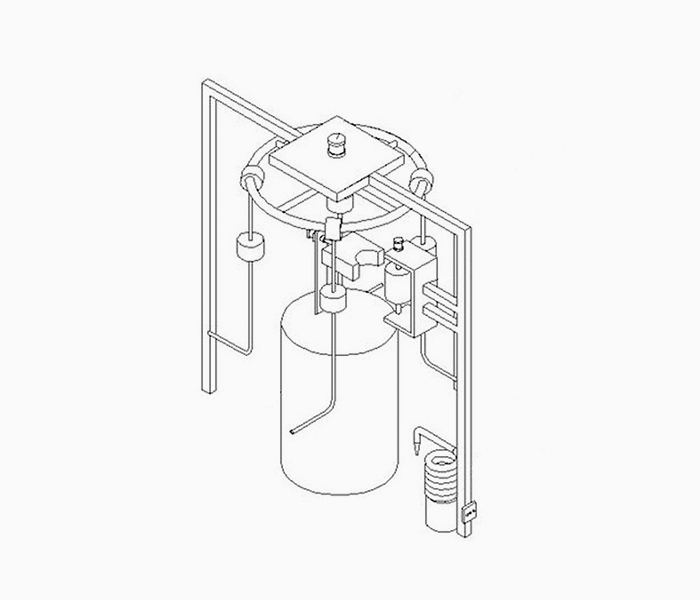

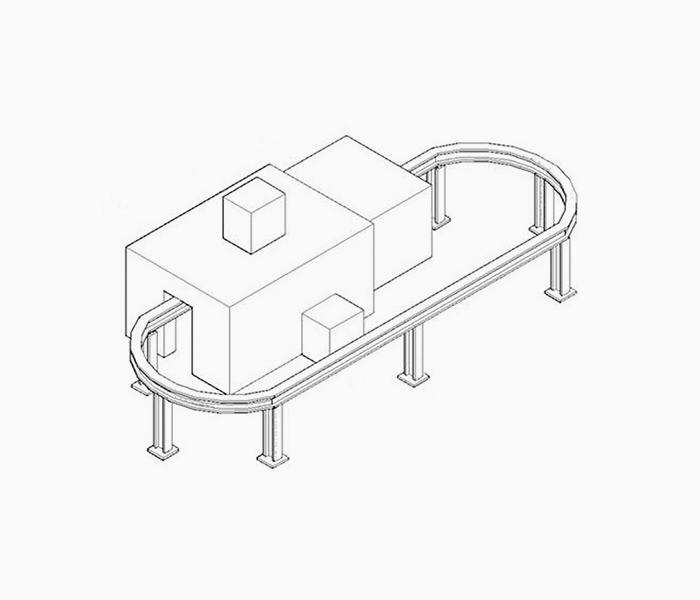

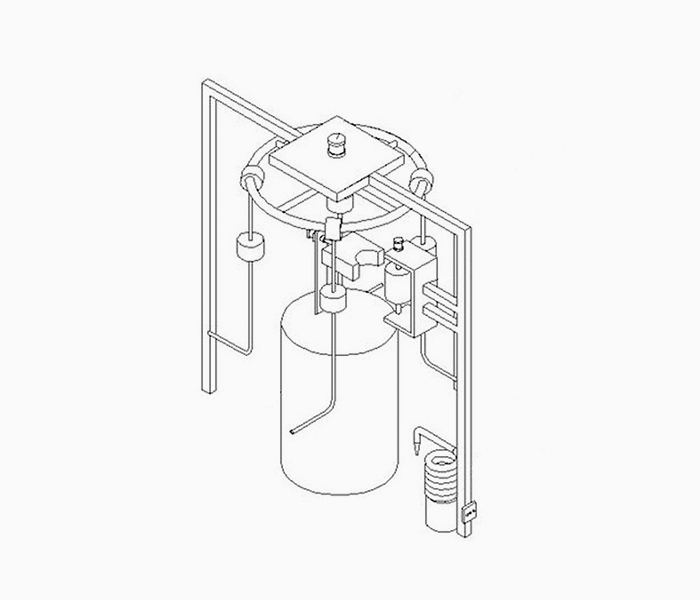

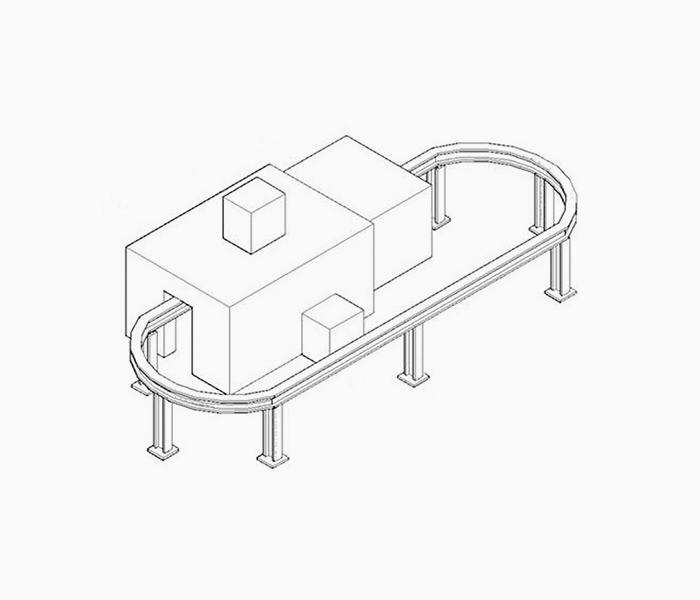

The cyclic drying line for painting of bicycle frame, includes a drying room, and a drying channel inside. One end of the drying room is connected with the paint spraying room, and the annular track runs through the paint spraying room and the drying room. The paint spraying rods and water curtain pipes are symmetrically set in the paint spraying room, the drying channel is connected with the burner, and the burner is set outside the drying room with a moisture removal processor equipped at the top. Through the circular track, the hanging frames are transported circularly, which is convenient for lifting and removing the frames. In addition, the finished products and the products to be processed are concentrated in the same area for easy management. At the same time, in the loading and unloading section on the circular track, it is also convenient to inspect the quality of the spray paint after drying.